How to make feed pellets

The process of manufacturing feed pellets involves multiple steps designed to process the raw materials into a pellet form that is palatable, nutritious, and easy to store. The following is the basic process flow, technical recommendations and feed pellet diameter recommendations for manufacturing feed pellets.

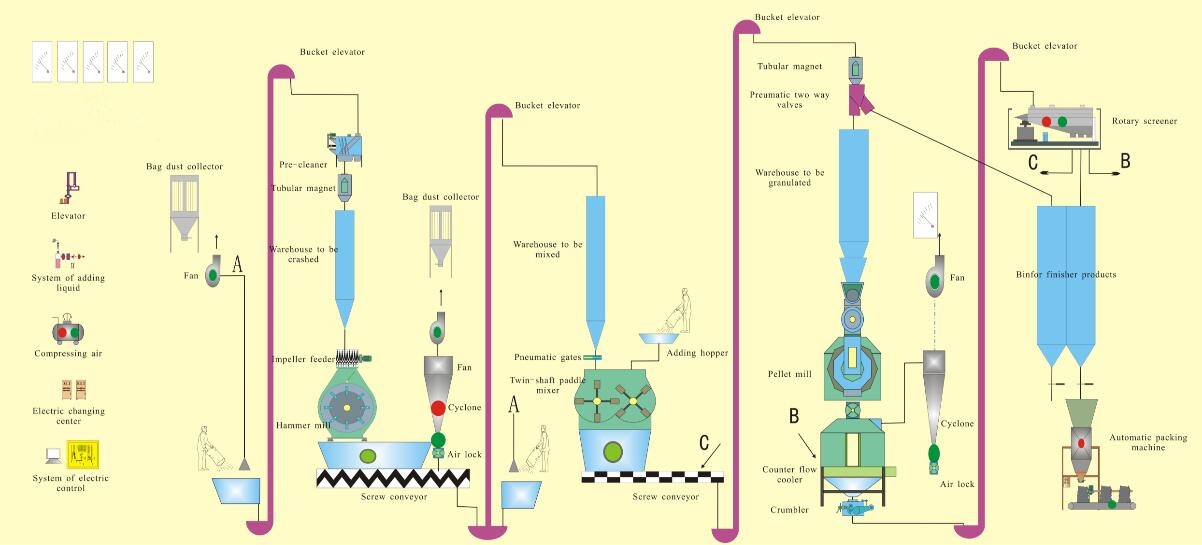

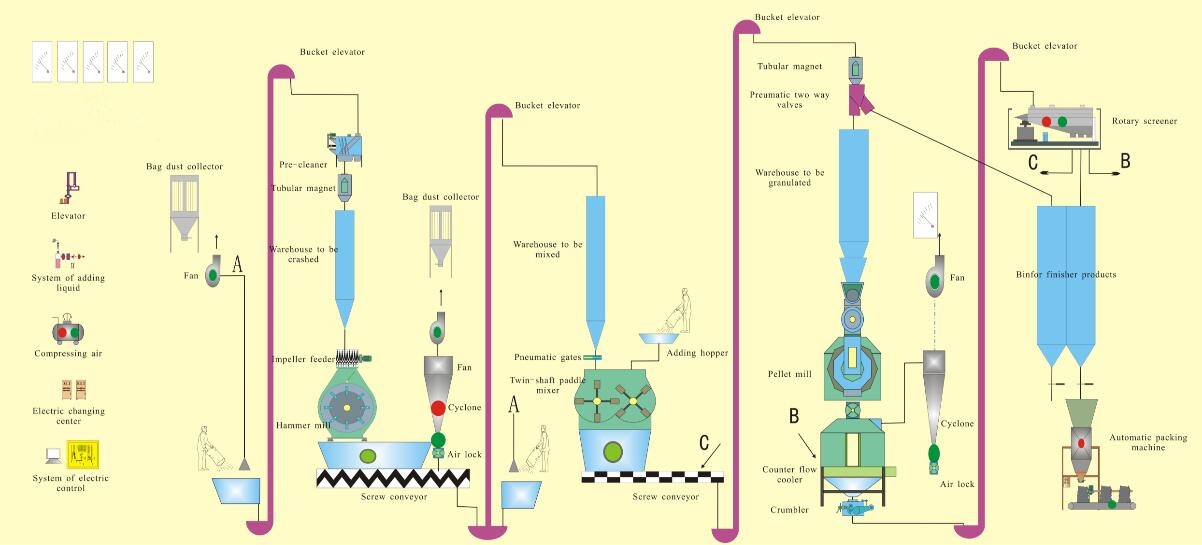

Process Flow

-

Raw material reception and preprocessing: Check raw material quality, remove impurities, and crush raw materials as needed.

-

Ingredient mixing: Weigh and mix different raw materials according to the nutritional formula to ensure even distribution of nutrients.

-

Grinding: Use a hammer or roller mill to refine the mixture to improve the digestion and absorption rate of the pellet feed.

-

Conditioning: Add water or steam to the powdered material for conditioning treatment to increase the temperature and humidity of the material to improve granulation efficiency.

-

Granulation: The conditioned materials are pressed into granules through a feed pellet machine. The size and shape of the particles can be adjusted according to the mold.

-

Cooling: Newly made pellets have a high temperature and need to be cooled to room temperature through a cooler to avoid mold growth due to high temperatures.

-

Screening: Remove dust and debris generated during the pelletization process to ensure the quality of pellet feed.

-

Packaging: The screened pellet feed is quantitatively packaged to facilitate storage and transportation.

Technical Advice

-

Formula design: The formula should be designed according to the nutritional needs of animals, and different raw materials should be properly matched.

-

Particle size control: Appropriate particle size facilitates animal intake and digestion, and the particle size can be adjusted according to the taste and digestion capabilities of different animals.

-

Quenching and tempering treatment: Appropriate temperature and humidity can improve the quality and hardness of the particles and reduce dust during the granulation process.

-

Equipment selection: Select suitable feed processing equipment and conduct regular maintenance and inspections to ensure production efficiency and product quality.

Recommendations for feed pellet diameter

Poultry

-

Broilers: For young broilers, the recommended pellet diameter is 2-3 mm; for adult broilers, pellets with a diameter of 3-4 mm are suitable.

-

Laying hens: Young hens from birth to 6 weeks old are suitable for pellets with a diameter of 1-2 mm, and adult laying hens are suitable for pellets with a diameter of 3-4 mm.

-

Duck: Young ducks (1-3 weeks old) are suitable for 2-3 mm pellets, growing ducks (4-7 weeks old) are suitable for 3-4 mm pellets, and adult ducks are suitable for 4-6 mm pellets.

-

Goose: Young geese are suitable for 3-4 mm pellets, and adult geese are suitable for 5-6 mm pellets.

Livestock

-

Pigs: It is recommended to use pellets with a diameter of 2-3 mm for weaned piglets, pellets with a diameter of 3-5 mm for growing pigs, and pellets with a diameter of 5-7 mm for adult pigs.

-

Cattle: Calves can use pellets with a diameter of 4-6 mm, and adult cattle (including beef cattle and dairy cows) are suitable for using pellets with a diameter of 6-8 mm.

-

Sheep: Young sheep can use 3-4 mm pellets and adult sheep is recommended to use 4-6 mm pellets.

Note:

Formula Suggestions

-

Energy and protein: Feed for animals in the fattening period should be rich in energy and protein to support rapid growth.

-

Vitamins and Minerals: Ensure the feed contains adequate vitamins and minerals to support bones, immune system and overall health.

-

Cellulose: For adult ruminants, the feed should contain a certain proportion of crude fiber to help promote digestion.

-

It is recommended to consult an animal nutrition expert on formulation design and particle size selection to ensure the specific needs of specific animal groups are met. Proper feed can increase feeding efficiency, improve animal health, and ultimately improve the economics of production.

Technical Advice

-

Particle uniformity: Ensure uniform particle size to avoid animals being picky eaters and ensure balanced nutritional intake.

-

Particle hardness: The particles should be hard enough and not easily broken to reduce losses during transportation and storage.

-

Nutritional balance: Adjust the formula according to the growth stages and physiological needs of different animals to ensure nutritional balance.