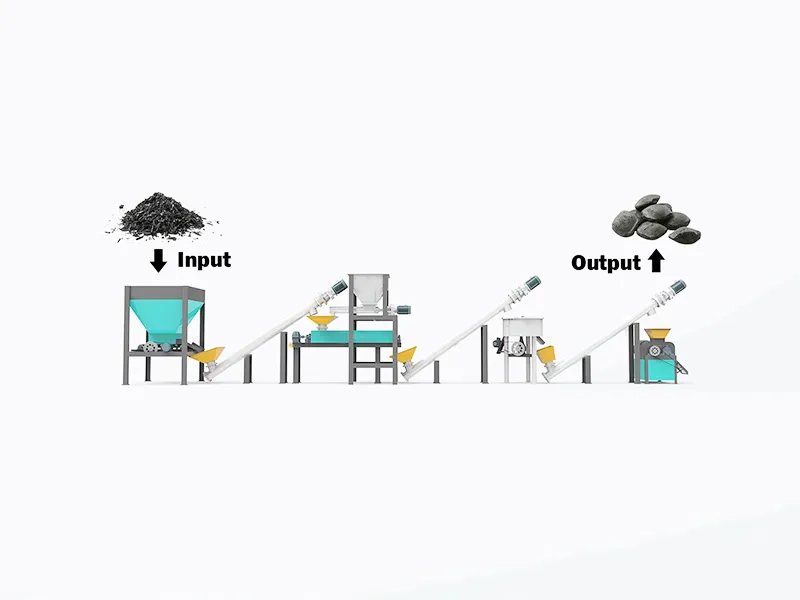

Charcoal Briquette Making Plant

Raw materials: coconut shells, fruit shells, bagasse, grape pomace, olive shells, hazelnut shells, palm waste, sawdust, bamboo, wood scraps, furniture waste, straw, rice husk, elephant grass, and various sludges

Model: HC-THX200, HC-THX300, HC-THX600, HC-THX1000

Capacity: 100 - 1000kg/h

Application: Barbecue and cooking fuel, Factory fuel (cement, boiler, brick, power plants), Smelting additive for steel and metals, Wastewater purification (absorbs impurities and odors), Raw material for fireworks, Air pollution control (absorbs ammonia gas), Carbon credits trading