How to make alfalfa pellets

Alfalfa is rich in protein and a large amount of mineral elements and carbohydrates, which reflect its nutritional value. Among them, the crude protein content is extremely high, about 17% to 23%. The rich protein in alfalfa is mainly concentrated in the leaves, and the protein content in chloroplasts is as high as about 30% to 50%, and the crude fiber content is about 42%. Therefore, alfalfa hay is roughage. Although alfalfa contains more crude protein, these crude proteins can be digested. Among them, the amino acid composition is similar to that of whey powder. Therefore, alfalfa is recognized as a high-quality forage for herbivores and is known as the "King of Forage."

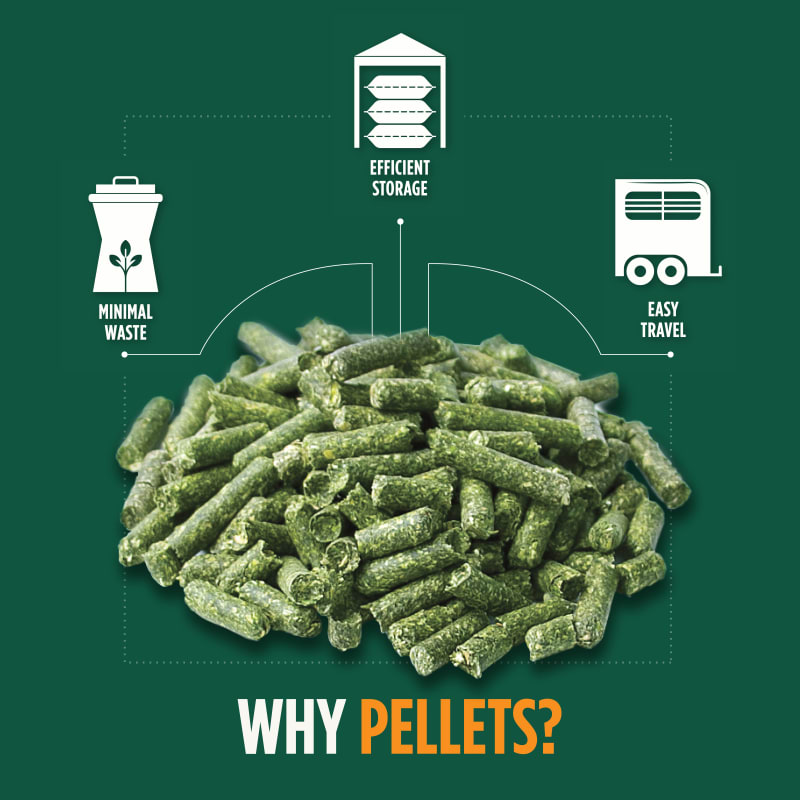

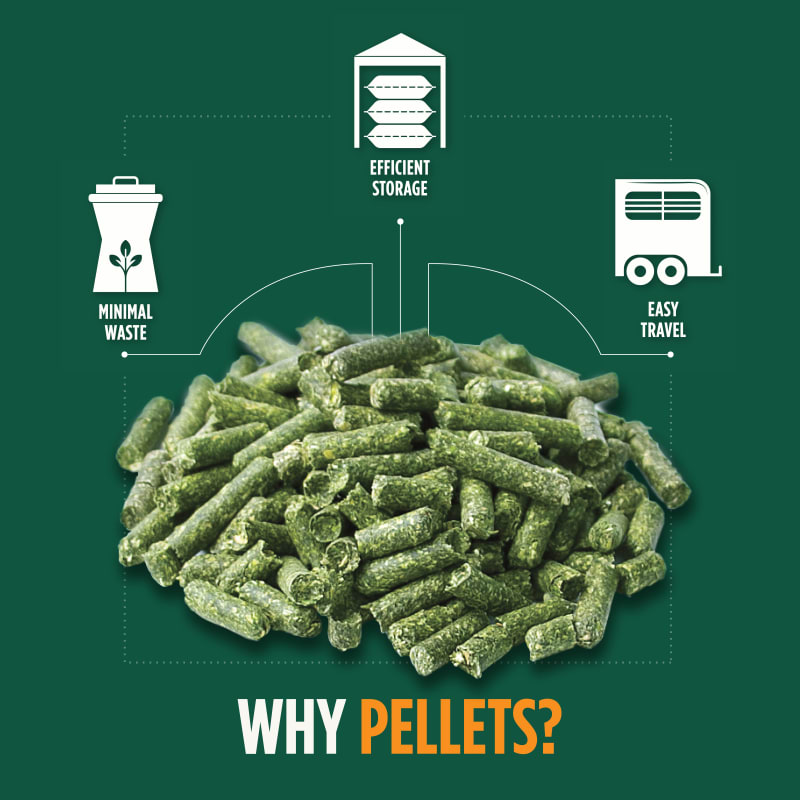

The process of manufacturing alfalfa pellets is similar to that of other biomass pellets, but given the specific characteristics of alfalfa, there are certain techniques and key points to consider. Alfalfa pellets are widely used in animal feed, especially for herbivores such as horses, sheep, and cattle.

Production Process and Techniques:

-

Raw Material Collection and Pretreatment: Collect high-quality alfalfa. The grass should be cut and allowed to air dry or be dried mechanically to reduce its moisture content. Ideally, the moisture content should be controlled between 10%-15%.

-

Crushing: The dried alfalfa is crushed using a crusher to achieve the appropriate granularity for better compression molding.

-

Moisture Adjustment: If necessary, the moisture content of the alfalfa may need to be appropriately adjusted to achieve the best compression effect.

-

Compression Molding: The processed alfalfa is fed into a pellet machine and compressed into pellets under high pressure. This step may require adjustments to pressure and temperature to ensure the quality of the pellets.

-

Cooling and Screening: The newly produced pellets need to be cooled using cooling equipment and then screened to remove non-standard pellets and excess dust.

-

Packaging and Storage: Package and store the pellets that meet quality standards to avoid moisture and contamination.

Technical Advice and Key Points:

Raw Material Quality Control: Choosing high-quality alfalfa is key to ensuring the quality of the pellets. Opt for green, nutrient-rich, and mold-free alfalfa.

Moisture Control: Controlling the moisture content is crucial, as too high or too low can affect the quality and formation of the pellets. Precise control through drying and humidification is necessary.

Adjust Compression Parameters: Adjust the pressure and temperature of the pellet machine based on the characteristics of alfalfa to optimize the quality and yield of the pellets.

Equipment Maintenance: Regularly check and maintain equipment to ensure the continuity of the pellet production process and long-term stable operation of the equipment.

Product Quality Testing: Regularly test the quality of the pellets during production, including the density, hardness, and moisture content of the pellets, to ensure the product meets standards.

The production of alfalfa pellets is a process that involves precise control and adjustments. Following the aforementioned production process and technical points can effectively improve the quality and efficiency of pellet production.