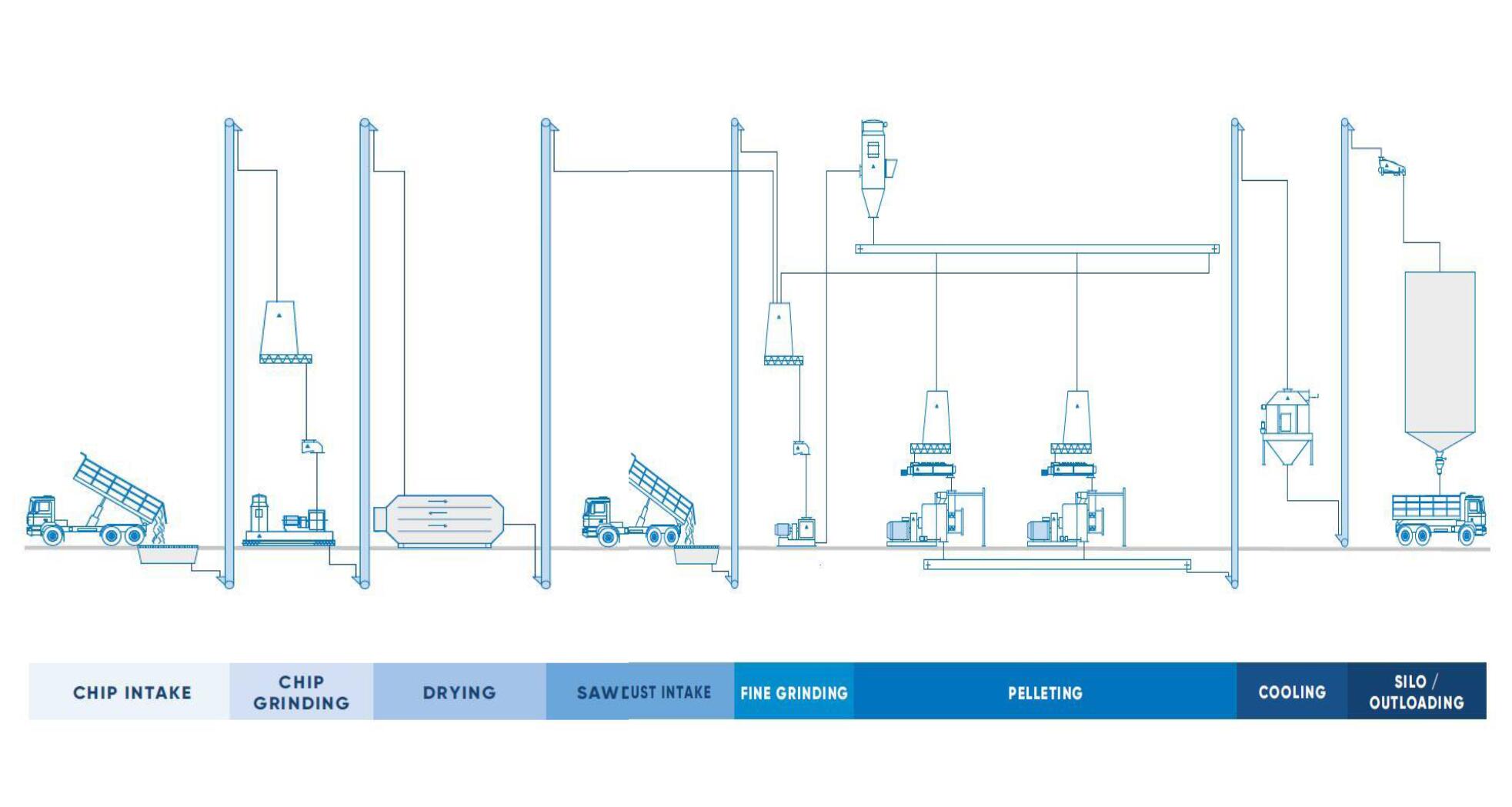

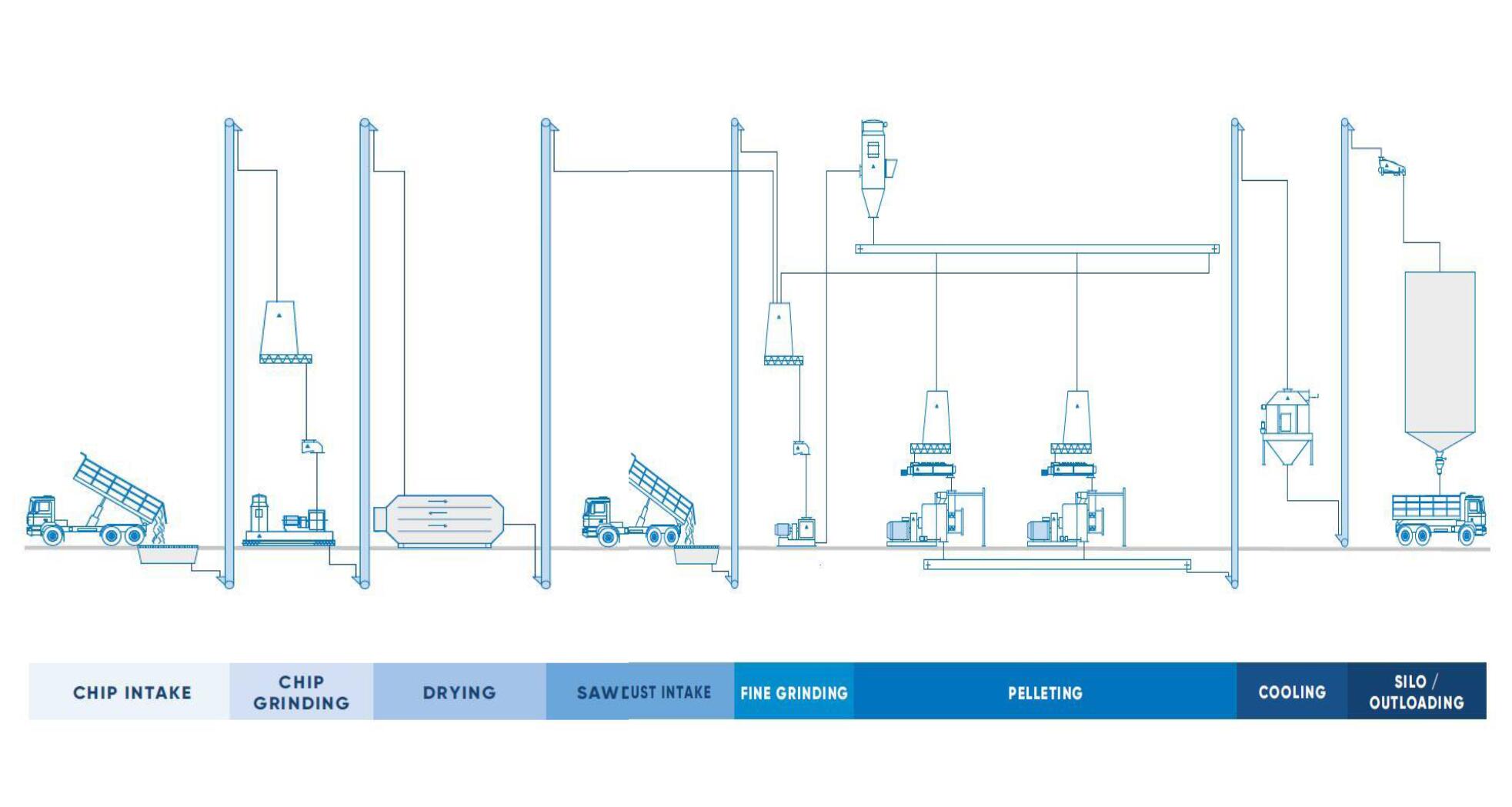

How to make biomass pellets fuel

Biomass pellets are a type of renewable energy made by processing biomass materials such as wood waste, straw, rice husk and energy crops. The manufacturing process mainly includes the following steps:

-

Raw Material Preparation: First, collect biomass materials, such as wood waste and crop straw. For some larger materials, it's necessary to crush them to meet the size requirements for subsequent processing.

-

Drying Process: Since biomass materials have high moisture content, it's essential to reduce their moisture through drying equipment, usually to 10%-15%. This step is crucial as improper moisture control can directly affect the quality and energy density of the pellets.

-

Crushing Process: After drying, the biomass materials are crushed through equipment like hammer mills to achieve the granularity suitable for pelletizing.

-

Pelletizing Process: The crushed materials are fed into a biomass pellet machine, where they are pressed into pellets through high pressure or molds. This step may require adding some binders to enhance the stability and durability of the pellets.

-

Cooling and Screening: The newly formed pellets are hot and need to be cooled through a cooler. Screening is then used to remove unqualified pellets and excess dust.

-

Packaging: Finally, the qualified biomass pellets are packaged for storage and transport.

In the manufacturing process of biomass pellets, the following technical suggestions might be helpful:

-

Moisture Control: Strictly control the moisture content of the materials, which is vital for ensuring the quality of the pellets and improving their calorific value.

-

Material Selection: The choice of materials or their mixing ratio can significantly impact the quality and energy density of the pellets. Proper selection can optimize product performance.

-

Equipment Selection and Maintenance: Choose efficient, stable biomass pellet production equipment and perform regular maintenance to ensure continuous operation and reduce the rate of failure.

-

Energy Efficiency Management: Improve energy utilization efficiency and reduce production costs by optimizing the production process and equipment configuration.

-

Environmental Compliance: Ensure that emissions during the production process meet local environmental protection requirements and take measures to reduce environmental impact.

Each step and technical suggestion need to be adjusted and optimized based on specific production conditions and objectives to achieve the best production efficiency and product quality.