Die selection is not always a straightforward and easy process.

The pelleting process is very complex, and over the years, researchers and industry professionals have evaluated ingredients, conditioning moisture, temperature, and time as well as die specifications. Of these factors, selecting die specifications is still often difficult. There are definitely reasons why die selection is not always a straightforward and easy process. Probably the greatest hurdle to overcome is the cost of a new die; depending on the size and die materials, this could be a $5,000-15,000 decision. If you order the wrong die, it’s not usually something that can be returned. Therefore, the intent of this article is to bring awareness to some of the factors to consider when working with your die supplier.

Die suppliers typically have a form that asks questions, such as die diameter and width, hole specifications, compression ratio, die materials (alloy), and relief design. However, before diving into these specifications, it is important to maybe step back and discuss the purpose of the die. The simplest answer is to form the conditioned mash into a pellet or cube, but unfortunately, there are a lot of factors to consider. The two needs that drive most pellet mill die selections are pellet quality and throughput. The challenge for most feed mill managers is to select the highest compression die that can be used to produce pellets of good quality and still maintain adequate throughput.

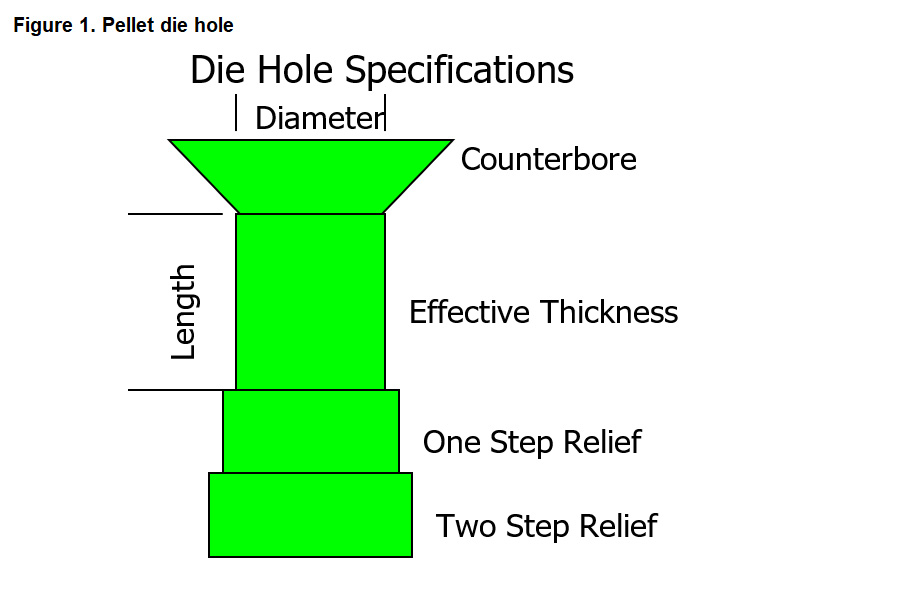

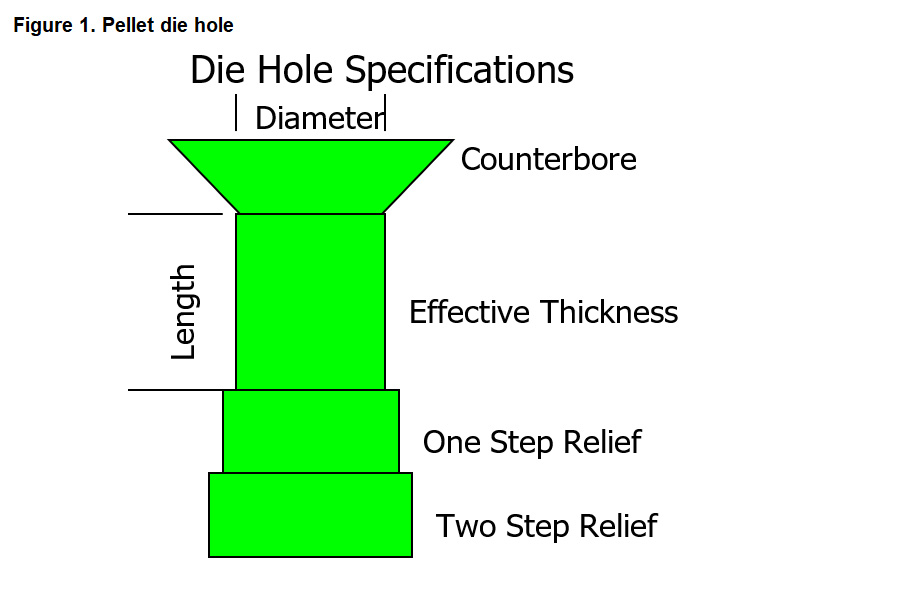

The first step in die selection is to understand the options for die hole specifications, of which there are many that can be applied to a die (Figure 1). The first specification is the hole diameter, which can range from 1/8” pellets to 3/4” cubes, with the most popular sizes being 5/32, 11/64 and 3/16” (4.0, 4.4, and 4.8 mm). As the diameter of the holes decreases, there will be a reduction in throughput due to less open area for the feed to pass through the pellet die. However, this can be somewhat overcome by increasing the number of the holes in the die.

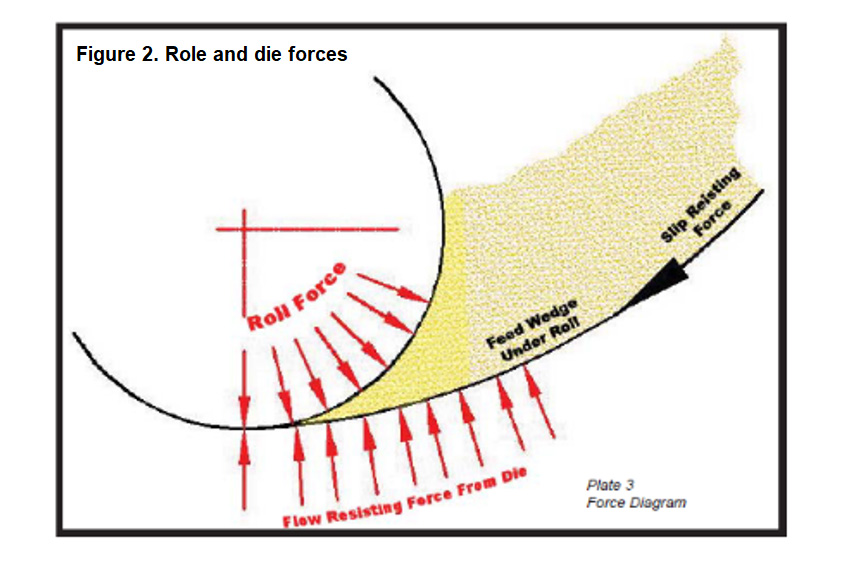

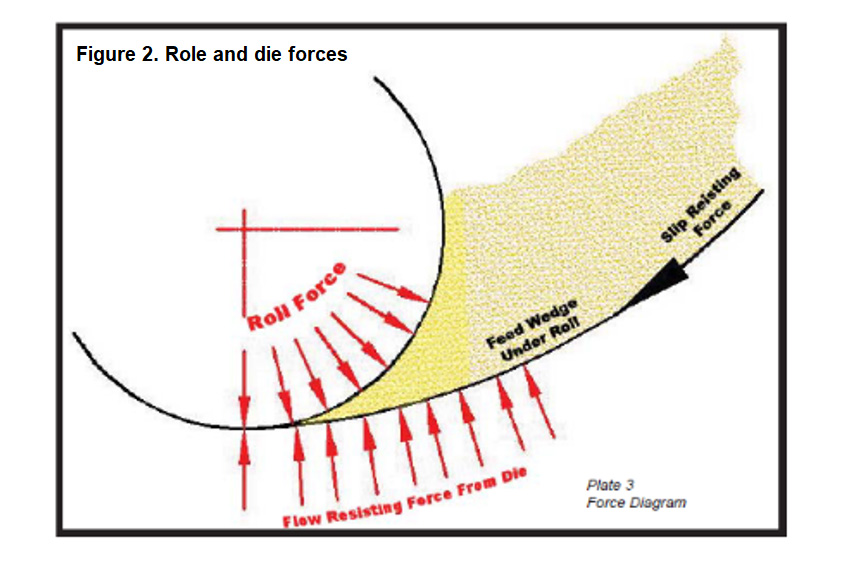

Another option is the counterbore, which is added to help funnel or direct the feed into the hole. But, as the die wears or the rolls are over tightened to the point of running metal on metal, the counterbore is rolled over and blocks the flow of the material into the hole. The effective thickness or length is where the majority of the compression occurs to form the pellet. The greater the thickness, the higher the compression. In general, as the die thickness increases (assuming that hole diameter does not change), there is a decrease in throughput as more work must be applied to force the feed through the die due to the flow resisting forces of the die working against the roll (Figure 2). Reduction of these forces can be accomplished through step relief of the die from the outside, which helps the pellet exit the die.

There are different setups that can be used. Some of the most common are applying relief equally across all holes or having more relief on the outer rows of the die to facilitate the flow of material through the outside holes. This is an important specification to consider because feed on the outside rows has two flow options. The first is to flow through the hole while the second is to squeeze out the side of the roll, which returns feed back to pelleting chamber and decreases throughput.

Operators should inspect the outside rows of the pellet die when the pellet mill is down to make sure feed is flowing through the outside rows. If feed is not flowing through the outside rows, there is likely to be a significant loss in throughput.

Finally, there is the L:D ratio, or the effective thickness divided by the hole diameter. For example, a pellet die with 11/64” (4.4 mm) diameter holes that has 1.75” (45 mm) of effective thickness has a L:D ratio of around 10.2 (1.75” ÷ 11/64”). Increasing the L:D will normally produce a higher quality pellet as measured by the pellet durability index (PDI) as long as temperature and moisture levels remain constant. However, in many instances as the L:D is increased, the temperature may need to be decreased because the flow resisting force of the die is greater than the roll forces and the rolls start slipping with the original moisture content.

That’s the science of the die, but the art of the pelleting process is trying to find the proper balance between L:D (compression), conditioning temperature, and moisture to achieve the desired pellet quality. As they say, this is where the rubber meets the road and the experienced pellet mill operators are worth their weight in gold. The challenge for the feed industry is that we are a least cost formula and byproduct industry with changing weather conditions, formulas, and ingredients, each of which can significantly affect pellet quality and throughput. While some operators and managers just throw up their hands and say it’s not a battle that can be won, others take a very systematic approach, such as keeping detailed records on each production run, monitoring moisture content, adjusting fat levels added into the mixer, keeping dies of different compression ratios in their inventory, and changing out dies based on pellet quality and throughput.

The best advice we can leave you with is to monitor the process, discuss different die specification options with your die supplier and do not be afraid to make a die change. The reality is that the cost of the pellet die is relatively low compared to the cost of electrical energy and labor that goes into the pelleting process. Don’t focus on one single cost, but instead on the overall expense and efficiency of the pelleting process.

Finally, if you are looking for more information on die selection, please contact us.